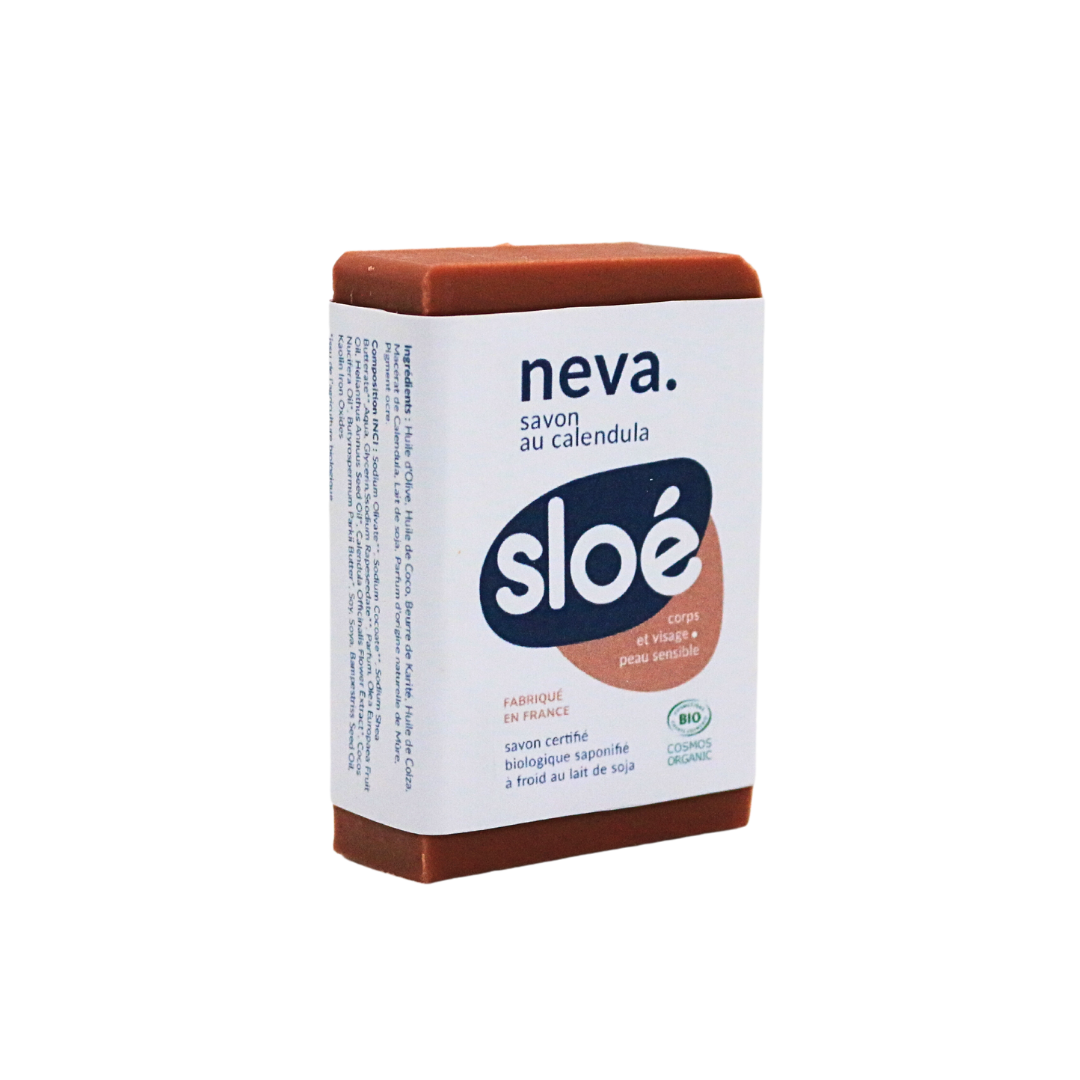

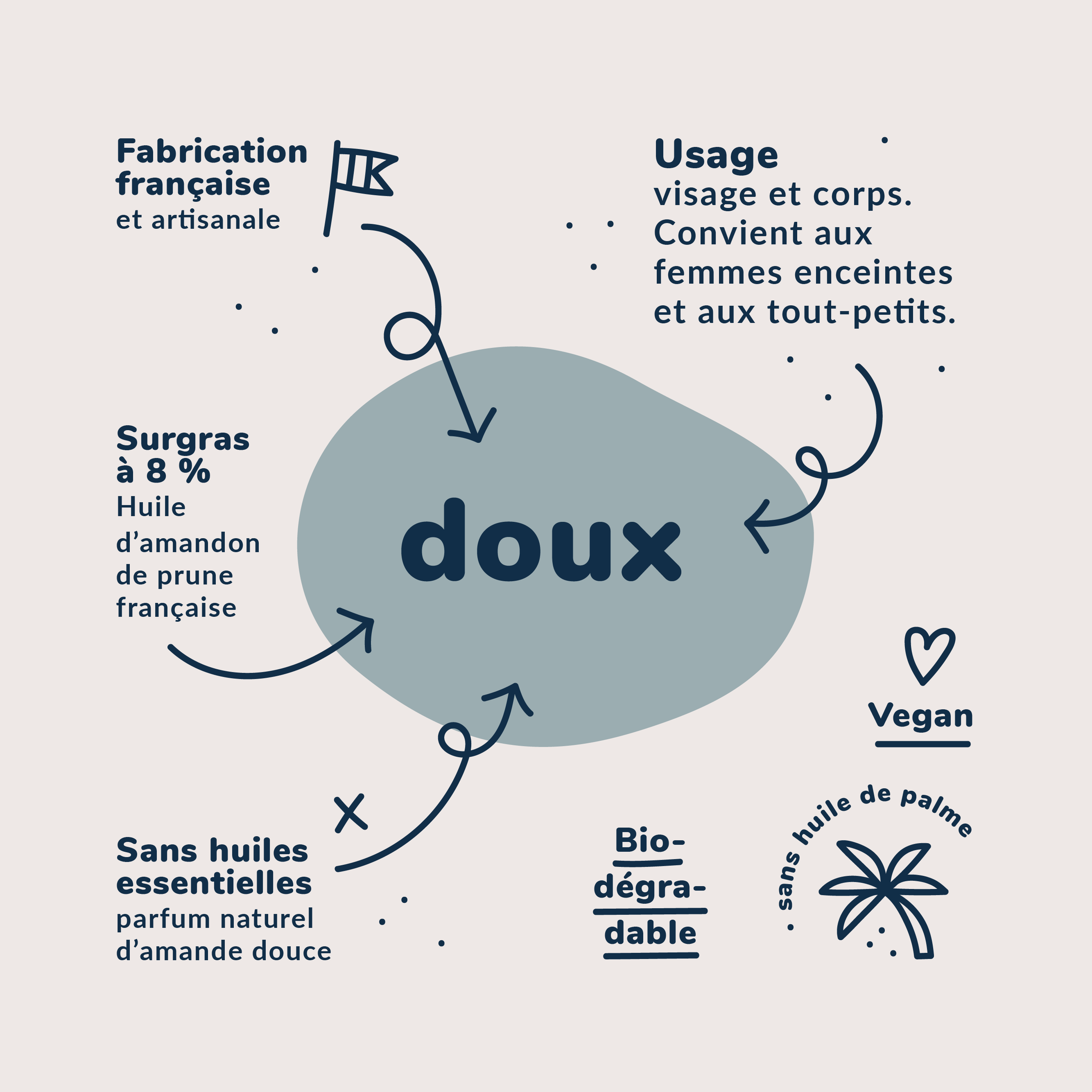

Il s'agit d'un procédé de fabrication unique, écologique et artisanal qui garantit la meilleure conservation possible des propriétés des huiles et beurres végétaux utilisés.

Cette méthode de fabrication permet d'obtenir des savons de qualité supérieure. Dans chacune des formulations nous ajoutons des huiles végétales certifiés bio en fin de fabrication de façon à obtenir un surgras de 8 à 10%, idéal pour la peau.

Tous les colorants utilisés sont 100% d'origine naturelle.

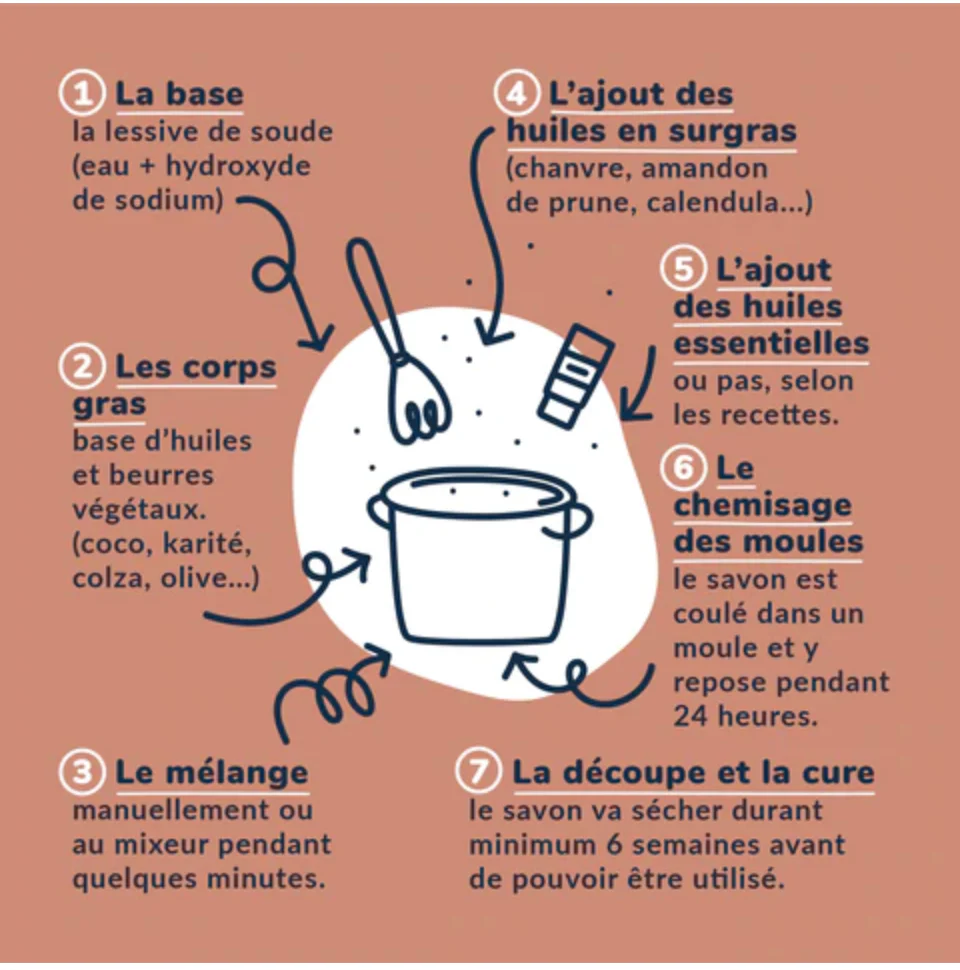

Pour fabriquer un savon solide il faut deux éléments : un corps gras soit un mélange d’huiles végétales d’un côté et de l’autre, une base de soude, ou hydroxyde de sodium pour les intimes.

De ce mélange va se produire une réaction chimique qui va donner naissance à deux éléments : la glycérine et le savon. La réaction chimique est totale ce qui veut dire que la soude est totalement absorbée. Et pour obtenir un savon surgras la quantité d’huile doit être plus importante que celle de la soude.

Nous pratiquons un retrait de soude de 5%

Un savon pas comme les autres...

Chaque huile contient des éléments non saponifiables (qui ne réagiront pas avec la soude) qui apporteront une propriété spécifique au savon selon la nature de l’huile.

La saponification à froid se fait en général à température ambiante. Nous travaillons à des températures plus basses que ce qui pourrait être pratiqué chez d’autres dans le but de protéger les matières premières.

Enfin, pour faire un savon de bonne qualité il faut surtout avoir une connaissance parfaite des huiles végétales, huiles essentielles et parfums d'origine naturelle utilisés. La preuve ? Tous nos cosmétiques sont labellisé COSMEBIO (Cosmos Organic)

découvre nos produits