"Bonjour, en quelques mots, ma femme et moi partons pour 2 mois et demi de voyage en Zambie, Botswana et Namibie. Nos passions sont le kayak, le rafting et les animaux.

Notre mode de transport pour ce voyage : un 4x4 avec une tente de toit pour être au plus proche de la nature sauvage :) "

best seller

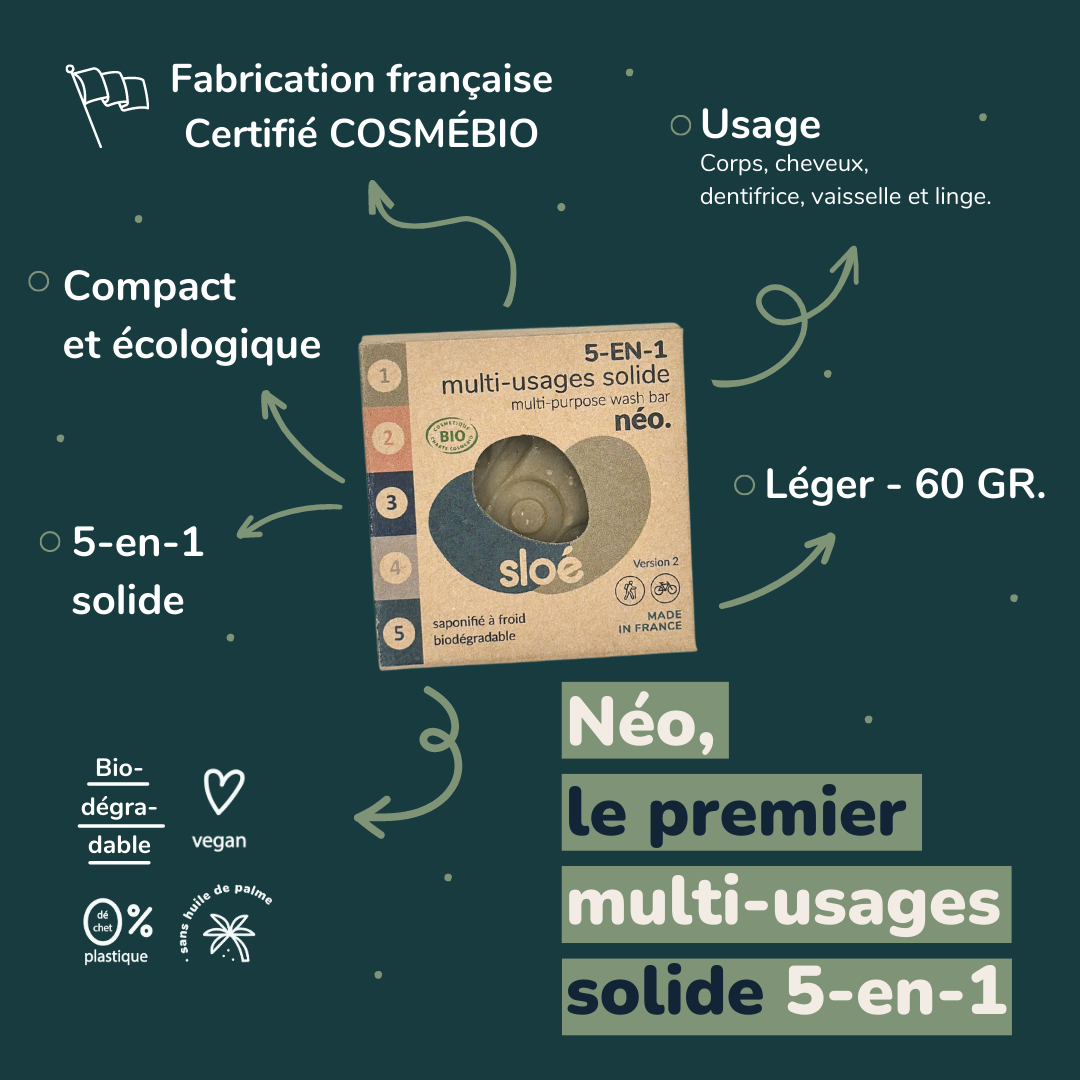

Neo: the first 5-in-1 solid multi-purpose product (60GR.)

Sale priceFrom €9,90

Toothpaste solid tablets - mint

Sale priceFrom €6,90

Kivu: solid deodorant stick (50ml)

Sale price€11,90

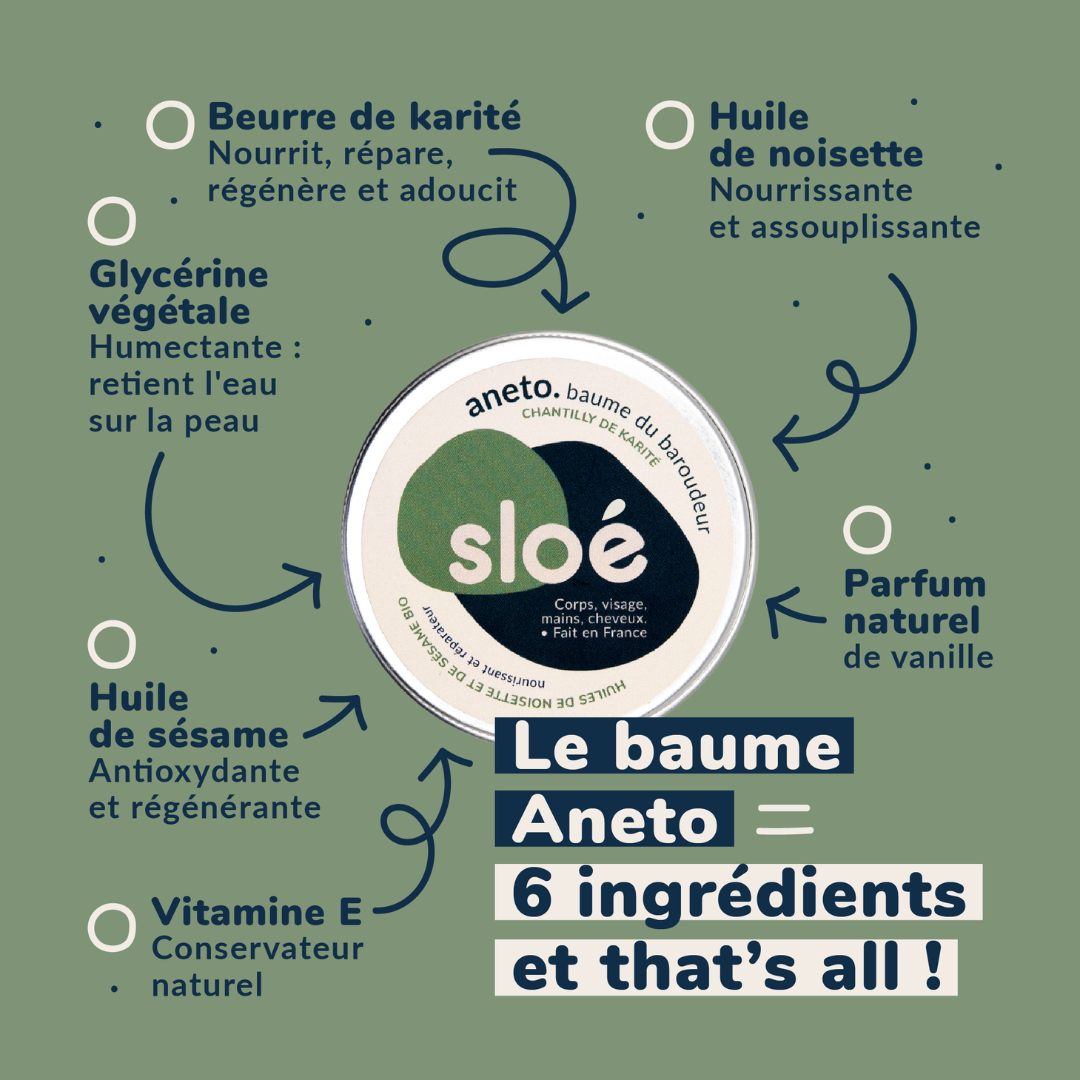

Aneto: the nourishing, repairing multi-use balm

Sale priceFrom €10,90